| Market Overview

As power generation equipment and backup power supply, fuel cells can be widely used in transportation and industrial fields, greatly alleviating the energy pressure caused by the depletion of fossil fuels. Its zero-emission and renewable advantages make it one of the most potential energy supply solutions. The preferential policies currently implemented by various countries have promoted the rapid development of the global fuel cell market.

The system can be simply classified according to the internal electrolyte of the fuel cell: Alkaline Fuel Cell (AFC), Phosphoric Acid Fuel Cell (PAFC), Molten Carbonate Fuel Cell (MCFC), Solid Oxide Fuel Cell (SOFC), Proton Exchange Membrane Fuel Cell (PEMFC). Currently SOFC and PEMFC are the most popular research directions.

| Market pain point

Research and improvement of fuel cells have always focused on improving efficiency and system operating stability, as follows:

1. Stable high-temperature operation: The precious metal catalyst of the fuel cell must be at an appropriate temperature to show good activity and stability. In order to ensure the most efficient electrochemical reaction, it usually needs to be stable between 80 and 95°C. If the temperature is too high or too low, the power generation efficiency will be reduced.

2. Precise control of water volume: In the actual operation of proton exchange membrane fuel cells (PEMFC), the dynamic water volume in the system is difficult to control. If excess water is not discharged in time, the membrane electrolyte will be flooded. If too little water is not replenished in time, it will reduce the overall performance of the battery and even have a negative impact on the life of the membrane.

3. Long-term stable operation: Fuel cell systems are usually designed for long-term operation. The core components of the system, such as the proton exchange membrane, need to have continuous operation performanceand a lifespan of several years to decades.All other accessories need to match its performance.

4. Leakage and cleanup: Core components are expensive, and system use requires regular maintenance and cleaning, and a special monitoring system. Once the pipeline liquid leaks, the electrochemical reaction will be interfered with, and even the key components of the battery stack will be corroded and damaged, polluting the environment, causing maintenance and economic losses.

| TOPSFLO solution

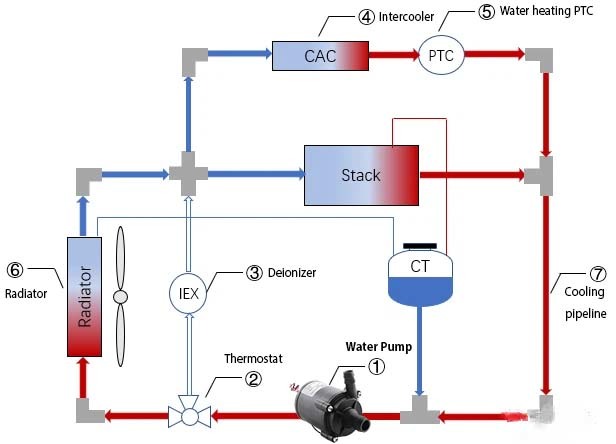

Water pumps play an important role in fuel cell systems, and TOPSFLO centrifugal pumps perfectly solve the needs of multiple uses:

1. The TOPSFLO water pump has been measured to operate continuously for 3,000 hours at a liquid temperature of 95 degrees, and can easily cope with the high-temperature liquid circulation requirements of the battery system. The C01 pump circuit board fully considers the temperature rise margin in the design and material selection, and has divided the strong and weak currents. It is matched with internationally renowned brand electronic components to help the system continue to maintain a stable working state.

In response to the different water management requirements of the fuel cell system under different loads and working conditions, the water pump with PWM speed regulation function can be customized. That is, the battery system sensor dynamically controls the water supply of the pump based on the monitored battery load and environmental conditions such as flow, pressure, temperature, and liquid level to ensure efficient operation of the system.

The laboratory testing service life exceeds 20,000 hours, directly matching the long life requirements of the core components of the fuel cell. The moving components adopt wear-resistant design to greatly reduce operating wear. For example, without carbon brushes, self-produced ECM brushless motor, imported graphite bearings and ceramic shafts with good self-lubricating properties. Extends the life of cooling components and significantly reduces the risk of equipment repairs and downtime.

In order to ensure no leakage, TOPSFLO water pumps are 100% air tight tested before leaving the factory, and the ultimate pressure can reach more than 18 Bar. As a rare moving part in the fuel cell system, high-quality water pumps can reduce the risk of pipeline leakage in the fuel cell system, ensure that core components work in a safe environment, and reduce system failure maintenance costs.

Charging piles are equipped with intelligent management systems, which need to realize remote management, monitoring and data analysis, etc., and therefore cannot be subject to electromagnetic interference from other components.

In order to meet the needs of cold-plate liquid-cooled servers, Topsflo Pump has specially designed a water pump with a unique flat design for them, which can better solve the problems currently encountered by server manufacturers:

Stay tuned..