Leading industry development with advanced manufacturing; Create maximum value for customers with core manufacturing capabilities

-

01

Lean Production System

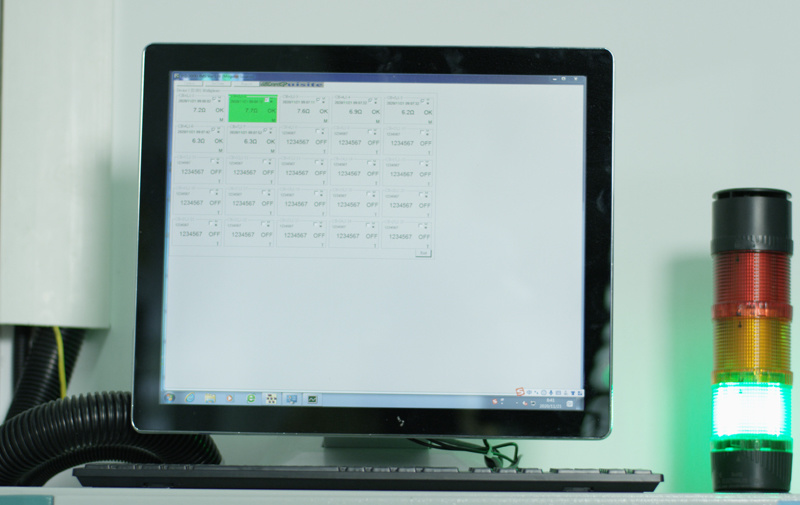

MSA operation management system,

Ensure the accuracy and validity of inspection measurement results -

02

Refined and visualized on-site management

Standardize the work flow of process inspection. Strictly follow the 6S management regulations, maintain and improve the working environment and improve production efficiency

-

03

Anti-static Control

Professional ESD static control digital workshop, ESD system monitoring, following American standards, using the industry's most advanced static management system to prevent, detect, eliminate static electricity, and avoid product electronic failure caused by potential static electricity

-

04

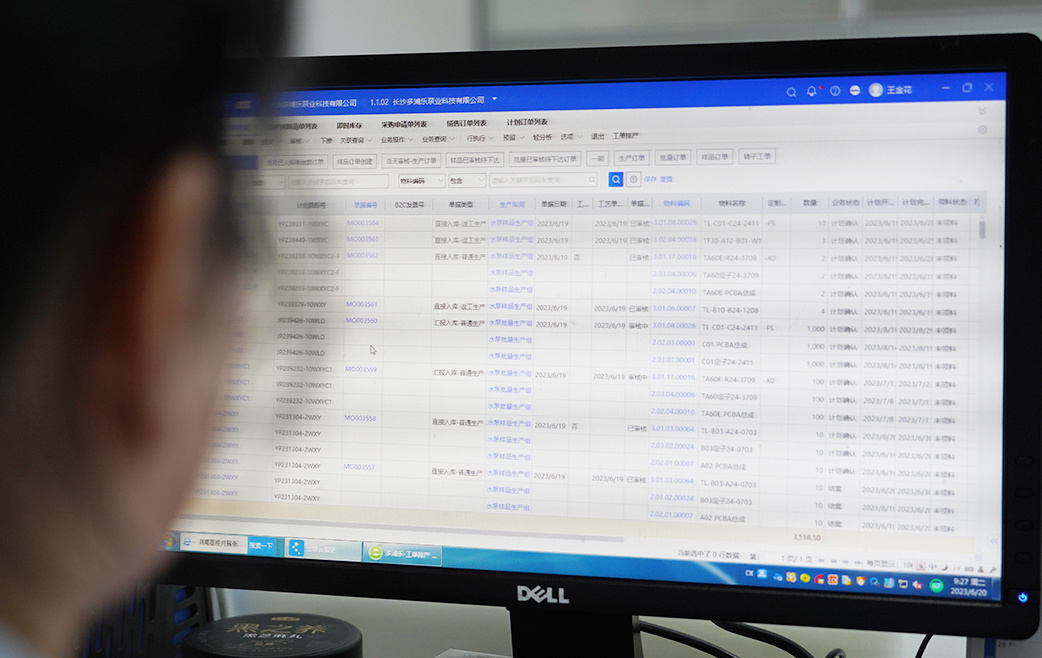

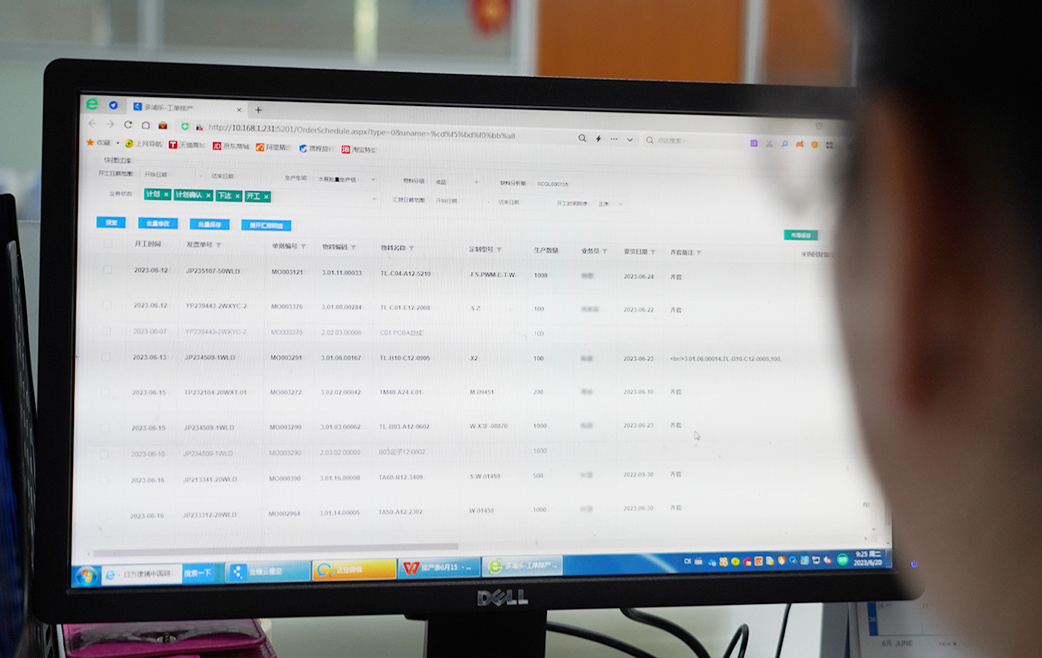

Order Delivery Management

The advanced information-based order management system is adopted, and all departments cooperate efficiently, and the production progress and delivery date are followed up at any time, so as to strictly ensure that the order delivery date is not delayed

Introduce advanced production & testing equipment from Japan and Germany; build intelligent electronic lines, fully automatic motor lines, and water pump assembly lines to ensure zero-defect product delivery on time

-

01

Intelligent Electronic Manufacturing Line

Each equipment of the electronic line adopts well-known brands in the industry, and is professionally customized in combination with our products. The equipment is stable and has strong operability

-

02

Investment in Automation Equipment

Invested more than 100 sets of advanced imported production and testing equipment to reasonably reduce human intervention and improve product accuracy

Transparent factory, ingenuity creates international quality