KTM, renowned for its exceptional quality, outstanding performance, and distinctive design, has established itself as the global leader in off-road motorcycles. It continues to set the standard in the industry, earning widespread recognition from off-road enthusiasts worldwide. The brand’s commitment to rigorous quality standards is fundamental to its success. As a trusted partner of KTM for over 12 years, Topsflo Pumps draws inspiration from this commitment to excellence.

KTM’s values and its unwavering focus on pump quality were key factors in the brand’s decision to choose Topsflo for its motorcycle cooling pumps.

Recently, we had the privilege of hosting KTM’s fourth factory audit. Let’s follow KTM’s example, take a closer look at Topsflo, and uncover the secrets behind our leading quality.

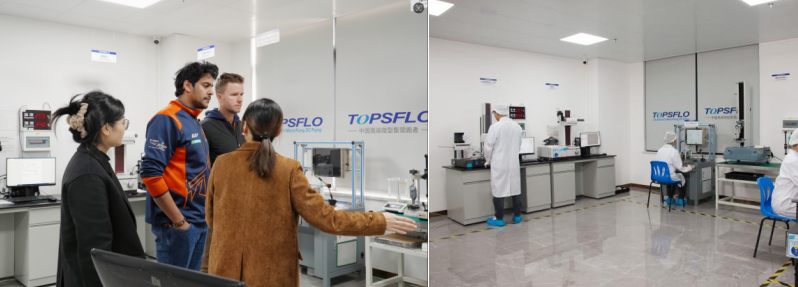

Step 1: R&D Laboratory Center

Topsflo allocates 10% of its annual revenue towards the development of R&D laboratories. To date, we have established four state-of-the-art research facilities that adhere to CNAS national laboratory standards. These include: a precision and physics laboratory, an electronic motor performance lab, an environment and durability testing room, and a noise test and analysis facility. Our dedicated R&D team consists of highly skilled engineers, many of whom have over 20 years of experience in the industry.

To ensure the highest levels of precision and accuracy in both product design and testing, we have invested in numerous advanced imported testing instruments. This enables us to provide robust support for product development and validation.

Currently, Topsflo has developed tailored motorcycle cooling pump solutions for over a hundred renowned companies worldwide, including several of the Fortune Global 500 firms.

Step 2: Anti-static dust-free production workshop

At Topsflo, we are convinced that exceptional quality stems from a conducive working environment. Our production facility adheres to the American ANSI standards, incorporating a comprehensive ESD (Electrostatic Discharge) management system. This ensures that our products are protected from potential static interference, using advanced anti-static controls to maintain the highest standards—something that our customers consistently appreciate.

The Topsflo production site operates under strict 6S management principles, ensuring a clean, organized, and efficient workspace. The materials storage is well-organized, with all materials stored in designated areas. Employees are expected to return materials to their original locations after use. This system helps minimize waste in terms of personnel, equipment, space, and time, significantly enhancing productivity, reducing production cycles, and lowering costs.

In addition, we have implemented smart production lines and integrated over 100 pieces of advanced equipment, all meeting international standards. This technological investment enables us to achieve both greater production efficiency and higher product quality.

Step 3: Fully automated injection molding workshop

In response to customer demands and the need for internal standardization in injection molding, along with on-site quality management requirements, Topsflo’s injection molding workshop strictly adheres to ISO 9001 standards. We have implemented a structured approach to injection molding quality management processes, ensuring that product quality consistently meets customer expectations. This commitment to ISO principles has been validated through multiple successful factory audits by key customers.

To further enhance production capabilities, Topsflo has introduced several sets of advanced imported injection molding equipment, along with supporting robots and conveyor systems. This integration has enabled the automation of plastic parts production, significantly increasing production efficiency. As a result, both the delivery speed and the overall quality of the pumps and plastic components have been greatly improved.

Step 4: Intelligent control of the warehouse

Step 5: Three phases of the new plant

In addition, we had the opportunity to host our customers at the new Topsflo Phase III factory. This new facility, set to begin production by the end of the year, will feature five automated production lines and over 100 pieces of high-end equipment, with the production hall’s automation rate expected to exceed 80%. This expansion will allow us to build a sustainable micro pump manufacturing plant that offers high-quality products, shorter lead times, and increased competitiveness.

During their visit, our customer shared KTM’s corporate philosophy and commitment to product quality, and they expressed their strong appreciation for Topsflo’s dedication to excellence in the field of brushless centrifugal pumps. They emphasized that the success of a brand lies in its unwavering commitment to quality and its pursuit of perfection.

When it comes to quality assurance, Topsflo strictly adheres to the ISO 9001 and TÜV 16949 quality management system standards, certified by Rheinland. From raw material selection to R&D, production, and quality control, every step is meticulously monitored. Approximately 80% of the raw materials used in Topsflo pumps are imported, and none of our materials are recycled. Additionally, all electronic components are sourced from renowned international brands. We also implement six rigorous 100% inspection processes that exceed both industry and national standards, ensuring that each pump is delivered to our customers in a “zero defect” condition.

It is through our rigorous quality assurance practices and unwavering spirit of innovation that Topsflo Pumps has been able to collaborate with top global brands like KTM, delivering exceptional product experiences. Moving forward, Topsflo will continue to uphold its commitment to quality and innovation, offering even better products and services to customers around the world.

Dear Amy and Penny,

Thank you so much for the warm welcome and wonderful day at Topsflo. It was indeed like meet up of old friends. Your team is so vibrant and we felt such a positive vibe from you and Thank You all so much for your whole hearted effort to keep the relationship with KTM with positive outlook for the points we have discussed.It is indeed my pleasure to work with your team where we have a positive outlook towards a future together.

We are looking forward to your visit to KTM.